18 Years Factory Telescoping Tube Plastic Parts - Stamping Aluminum – Walley

18 Years Factory Telescoping Tube Plastic Parts - Stamping Aluminum – Walley Detail:

Stamping Parts Advantages

Since press processing is often performed at room temperature, it is also called cold stamping. Stamping

forming is one of the metal pressure processing methods. It is a material forming engineering technology

based on the metal plastic deformation theory. The raw materials for stamping processing are generally

sheet or strip, so it is also called sheet metal stamping.

(1) The dimensional accuracy of the stamping parts is guaranteed by the mold, and has the same characteristics,

so the quality is stable and the interchangeability is good.

(2) Since it is processed by a mold, it is possible to obtain a part that is thin or light, has good rigidity, high

surface quality, and complicated shape, which is impossible or difficult to manufacture by other processing

methods.

(3) Stamping processing generally does not require heating of the blank, nor does it cut a large amount of

metal like cutting, so it not only saves energy, but also saves metal.

(4) For ordinary presses, dozens of pieces per minute can be produced, and high-speed presses can produce

hundreds of thousands of pieces per minute. So it is a highly efficient processing method.

Application

Stamping is not limited for Electronics & Communication Products and home hardware applications. Furthermore,

there are also some other important application fields in which hot forgings can showcase their strengths:

(1) Aviation industry

(2) Military industry

(3) Machinery industry

(4) Agricultural machinery industry

(5) Railway industry,

(6) Post and telecommunications industry

(7) Transportation industry,

(8) Chemical industry

(9) Medical equipment industry

(10) Household industry

| Size | M1-M36,As your drawings. |

| Available Material | Stainless Steel, Carbon steel/SS304/SS31,alloy steel,etc. |

| Surface treatment | Anodizing,Zinc/Nickel plated. |

| Certificate | ISO9001,IATF16949,ROHS |

| Quality control | ISO standard,100% Whole range inspection through the production |

| QC | thread gauge , callipers |

| Quality control | ISO standard,100% Whole range inspection through the production |

| Used | hydraulic vehicles ,automobiles, agricultural machines |

| After-sales Service | We will follow up every customer and solve all your problems satisfied after sales |

| Payment | TT;30% paid for deposit by T/T before production arrangement, the balance to be paid before shipment. |

Advantage

1) Offering video and photos with details freely during production.

2) Producing according to the accuracy of drawings, assembly measurement to detect function and strict quality control to ensure 0 return rate

3) 99% orders can be ensured delivery time

4) The materials we use are optimal

5) 24 hours online service

6) The competitive factory price with the same quality and service

7) The most suitable packing method to different products.

Other Stamping Products

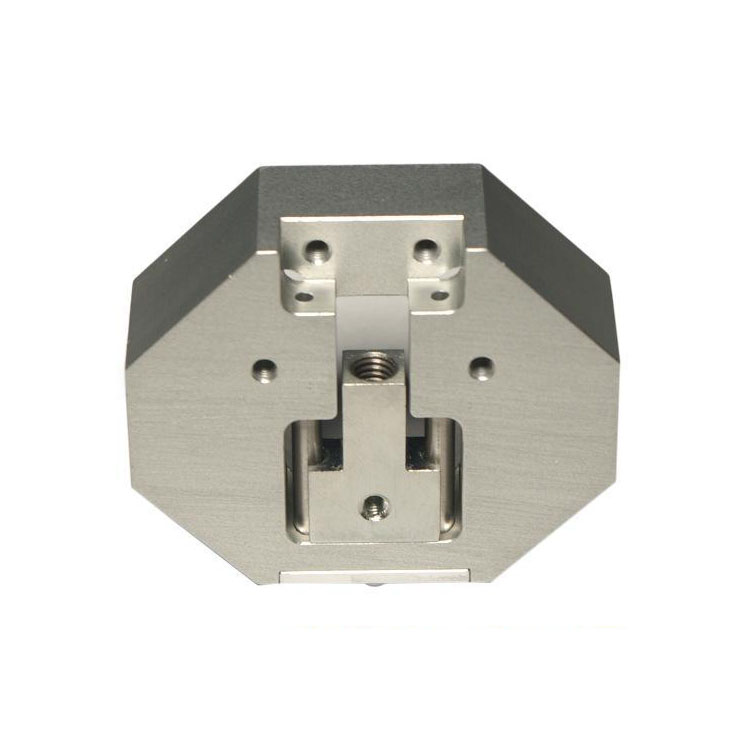

Product detail pictures:

Related Product Guide:

We hold strengthening and perfecting our items and repair. At the same time, we get the job done actively to do research and progress for 18 Years Factory Telescoping Tube Plastic Parts - Stamping Aluminum – Walley , The product will supply to all over the world, such as: Iran, Saudi Arabia, Germany, Our solutions are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.