Manufacturer for Surgical Instruments Component - Injection Molds Parts – Walley

Manufacturer for Surgical Instruments Component - Injection Molds Parts – Walley Detail:

As a leading plastic injection mold China maker, we specializes in making various plastic injection moulds for automotive, home appliances, medical equipment, electronics and sporting equipment, as well as general industrial OEM applications. Our company covers an area of more than 3,800 square meters workshop, surrounded with convenient transportation . At present, our group reaches to more than 150 excellent toolmakers in china and capital assets to more than 15 million RMB. Our capacity is 60-80 sets mould per month.

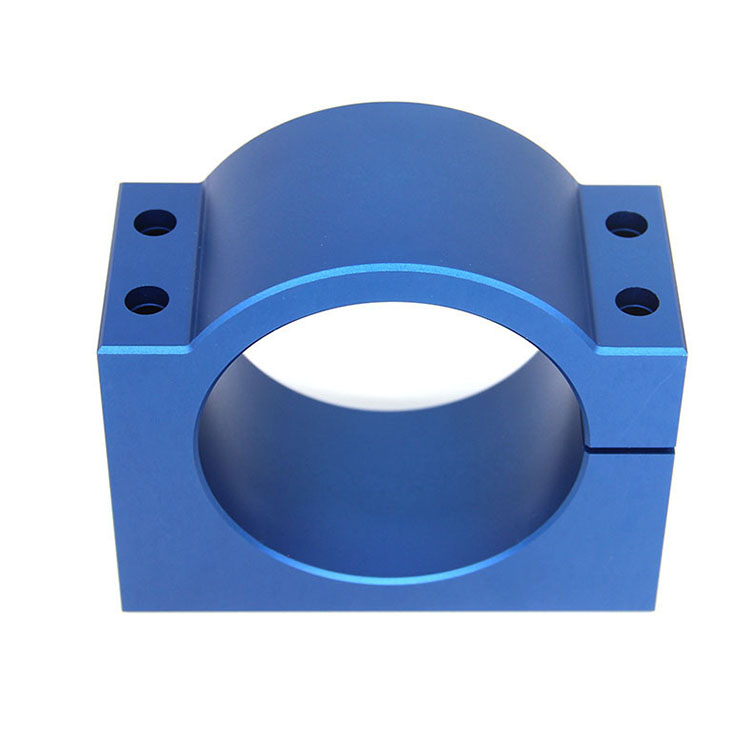

| product name | bushing |

| material | Nylon ,PC,PVDF, PTFE , Rubber,etc |

| Size | customized as your drawings,or samples |

| Features | Good anti-corrosion ability |

| color | White, black, or custom |

| Quality Certificate: | ISO9001:2008, ISO14001:2004 |

| Inspection quality system: | ISO standard, 100% Whole range inspection through the production. |

| Equipment: | Hardness test, torque test, endurance test, mechanical sizes test, ROHS report Mill test certification and etc as per your need. |

| Inspection process: | Incoming quality control →Process Quality Control →Final Quality Control → Pre-shipment Quality Control |

| Payment term | TT 30% deposit in advance, 70% Balance Before ship |

| packaging | bulk+carton+pallet ,small box+carton+box |

Recommand

Advantage

1) Offering video and photos with details freely during production.

2) Producing according to the accuracy of drawings, assembly measurement to detect function and

strict quality control to ensure 0 return rate

3)99% orders can be ensured delivery time

4) The materials we use are optimal

5) 24 hours online service

6) The competitive factory price with the same quality and service

7) The most suitable packing method to different products.

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and repair consciousness, our corporation has won a good popularity amid consumers everywhere in the environment for Manufacturer for Surgical Instruments Component - Injection Molds Parts – Walley , The product will supply to all over the world, such as: Austria, Malaysia, Naples, On today, we've got customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to deliver the highest quality products with best price. We've been looking forward to doing business with you!

Problems can be quickly and effectively resolved, it is worth to be trust and working together.