Aluminum Canoe Parts - Factory, Suppliers, Manufacturers from China

"Sincerity, Innovation, Rigorousness, and Efficiency" could be the persistent conception of our enterprise to the long-term to produce together with clients for mutual reciprocity and mutual profit for Aluminum Canoe Parts, Dressmaker Sewing Machine Parts, Aluminium Cnc Service, Bendix Air Brake Parts,Oem Aluminum Die Casting. We can customize the products according to your requirements and we can pack it for you when you order. The product will supply to all over the world, such as Europe, America, Australia,Mombasa, Israel,Albania, Costa Rica.Our company will continue to adhere to the " superior quality, reputable, the user first " principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

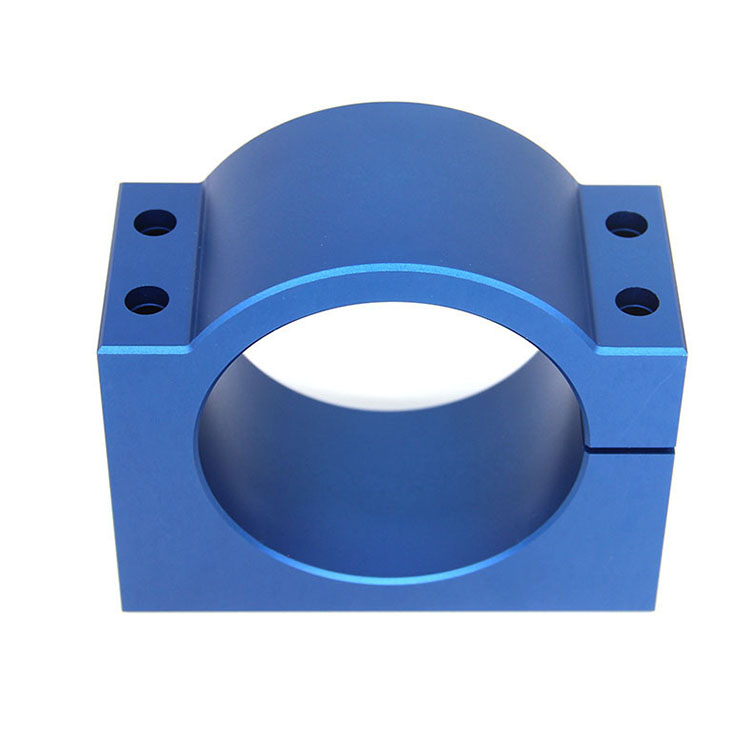

Related Products